How is Lithium Mined? Inside the Global Race for the World’s Most Useful Metal

Lithium has become one of the hottest commodities in the world. It fuels electric cars, stores renewable energy, powers cell phones, and other endless tech gadgets found in modern times. But one simple question people hardly seem to ask is how is lithium mined? It’s not a simple question, and the answer is highly localized and dictated by geology, geography, and technology. Learning about these methods makes clear the increased demand − and the challenges − in creating this essential resource.

Extracting Lithium from Saltwater: Mining Fish Chemical

Lithium is found under enormous salt flats in countries, such as Chile, Argentina, and Bolivia, known as the Lithium Triangle. And there, it is the brine sector that is being extracted.

How It Works

Deep beneath the surface, brine is pumped up to massive evaporation ponds. The water gradually evaporates with the help of sun and wind and deposits sediment rich in minerals. After months, it becomes concentrated enough for workers to extract lithium salts.

Why It’s Popular

It is less energy-consuming because it uses the process of natural evaporation instead of heavy machinery. Though, it does take a huge amount of water and extensive processing time.

In desert areas where saltwater deposits are found just below the surface, brine mining provides the answer to the question of how lithium is extracted.

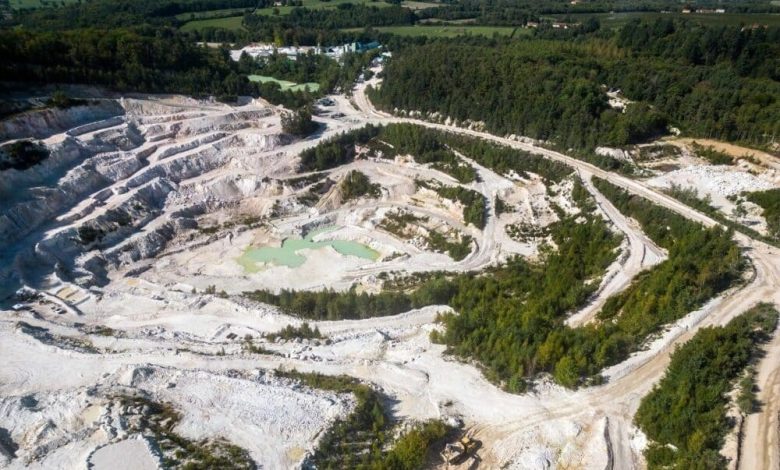

Hard-Rock Lithium: Mining the Ore from the Ground

In hard-rock lithium mining, nobody has the world beat Australia. Lithium is here in a mineral called spodumene, in formations under the earth that more-or-less look like granite.

How It Works

Open-pit approach was used by the mines for conventional ore extraction.

- They break the rock into small pieces.

- Great temperature alters the structure of the minerals above.

- The coarse ground rock is treated with chemicals to separate the lithium.

- Hard-rock mining provides fast output and enables mass production. It uses up a lot of equipment and energy though.

This process-part of a pre-production lithium pipeline-offers another glimpse into how is lithium mined; a more industrial, straight forward extraction method than from brine.

A Novel Approach to the Future: Direct Lithium Extraction (DLE)

New technologies are appearing as demand increases. The approach known as direct lithium extraction (DLE) hits closer to home, and aims to take lithium straight out of brine (rather than evaporating brine over months).

What Makes It Different

DLE employs filtration materials, ion-exchange systems, or absorptive compounds for fast lithium separation.

It takes up less land and can use less water, making it an exciting prospect for innovation going forward.

DLE is still in development, but could change how lithium has mined globally.

An Integral Part of the Discussion: Environmental Impact

Lithium mining has well-established clean energy benefits but faces environmental costs.

Concerns include:

- High water consumption

- Land disruption

- Waste from chemical processing

- Ecosystem pressure in mining regions

These problems are naturally making recycling lithium batteries a key component of sustainability.

Final Thoughts

And whilst in terms of how lithium is mined, one can only consider the way in which this resource may be more than an extraction process; it represents a concerted push positioning against stateside fossil fuels to enable more efficient and cleaner technologies booming worldwide. Extracted from brine, mined from rock, excavated with new methods, lithium occupies a central role in a low-carbon future. With increasing demand, mining techniques will continue to adapt and evolve to become ever-more efficient while minimizing environmental harm.